ABOUT US

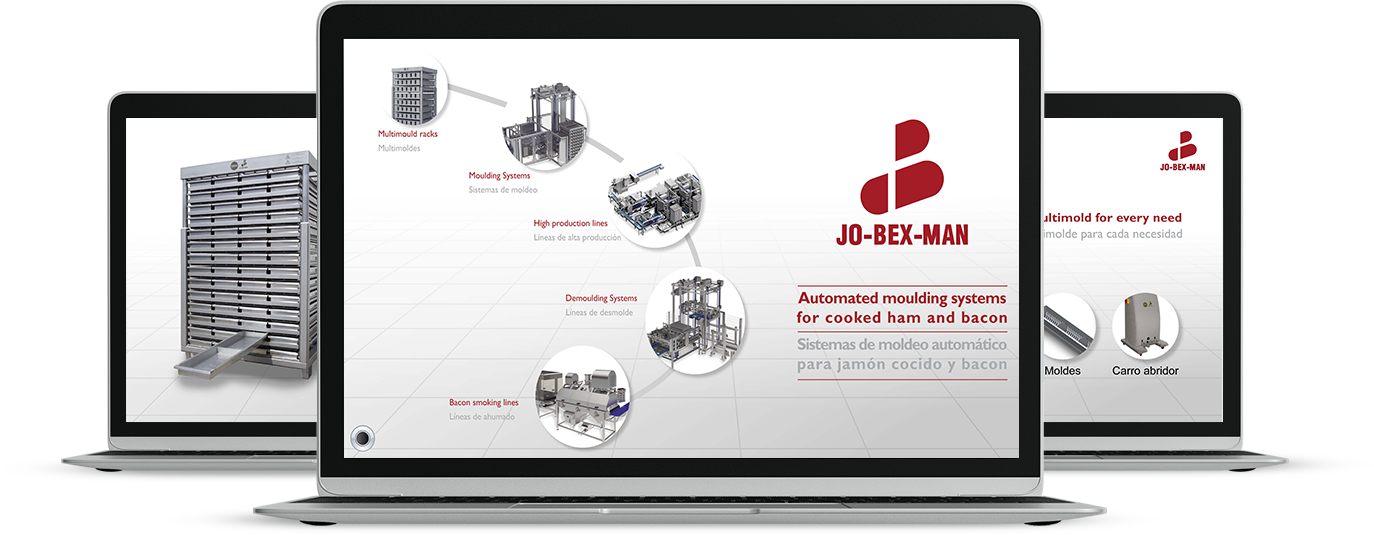

WE ARE SPECIALISTS IN AUTOMATING MEAT moulding LINES

JO-BEX-MAN® is a dynamic company with extensive experience in the moulding of meat pieces. We work with our own designs, technologies and patents to solve each of the different needs in terms of forming meats.

…through commitment and proximity to the client, we deliver maximum satisfaction in every project.

We continuously strive to offer our clients the most advanced technology. In an ever more automated world, it is important we incorporate technological improvements into our products so that we can offer the highest quality and productivity.

All of the machines and installations can be adapted to the needs of each client, integrating them with maximum efficiency into the production lines used. A great team of professionals will accompany you at every stage in the project to ensure the correct implementation and functioning.

We are delighted to have helped so many clients and to have found a solution for each of the needs they have presented to us over the years.

WHY CHOOSE US?

TEAM

We have a team of technicians and professionals who specialise in each of the tasks.

INNOVATION

We work hard to constantly improve our multimould rack system as well as the automated moulding and demoulding lines.

QUALITY

All of our machines are manufactured through guaranteed processes. They have CE certification and the highest level of protection against external agents (IP69k protection).

SERVICE

We provide complete monitoring of the project until it is installed and working correctly.

R&D DEPARTMENT

One of our main assets is the high-tech R&D department, which explores continuously optimizing the systems of moulding in every single field such as:

- Increase the product’s final performance

- Improving sliceability of pieces avoiding breakages

- Improvement of the appearance and uniformity of the finished product

- Optimize time cooking and cooling of moulds

- Total and partial automation of moulding processes.

WHAT WE OFFER

Our extensive experience enables us to tackle any type of project to improve the performance and productivity of meat moulding and demoulding lines with guarantees, moving forwards to offer the most advanced technology at all times.

- Qualified technical team

- Flexible and adaptable systems

- We take care of all of the design and manufacture process

- We monitor every installation

- Technical service

- Rapid shipping of replacement parts

- Distributors all over the world

- Options for expanding and improving installations

Over the years we have built on the experience from each project to improve and offer higher quality solutions every day.

Constant innovation and development are our main objectives so that we can improve with every project.

Our greatest achievement is ensuring that our clients are satisfied with every piece of our work, regardless of the scale of the project.

Thanks to the network of distributors we have established over the years, we can work for clients all over the world.