WE DESIGN A MULTIMOULD FOR EACH NEED

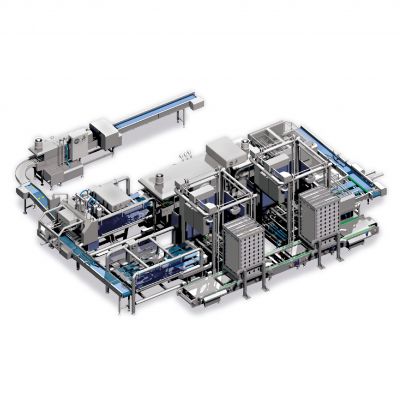

Each multimould is made to measure according to the needs of the client. We have a wide variety of moulds designed for each type of product to achieve the best cooking and finished appearance. All multimoulds are ready for automation

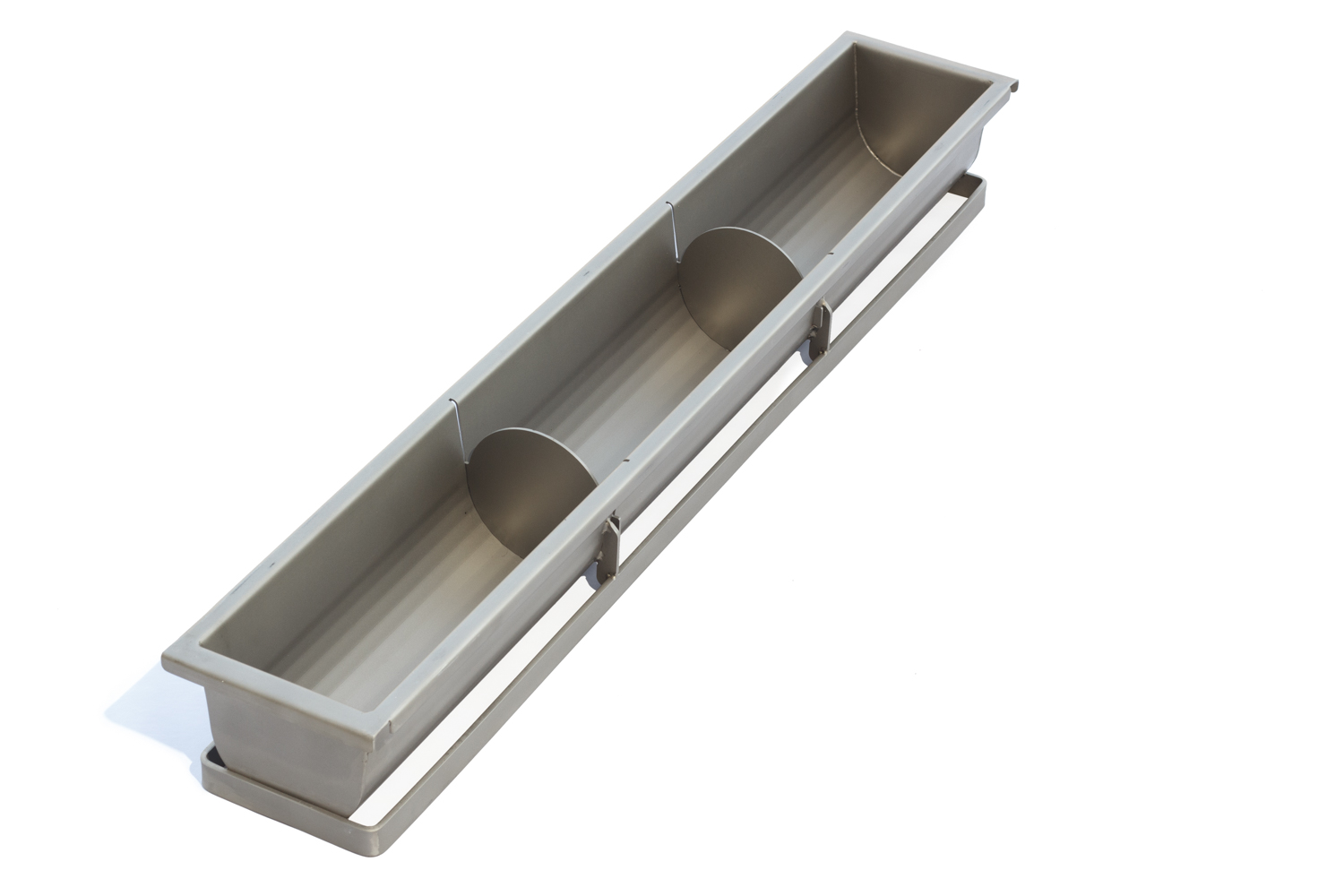

Multimould for shaping rectangular pieces of cooked ham.

- Type of base: Fixed feet

- Capacity: 60 moulds

(6 × 10 levels) - Products per mould: 3

Multimould for shaping rectangular pieces of bacon

- Type of base: Fixed feet

- Capacity: 56 moulds

(4 × 14 levels) - Products per mould: 1

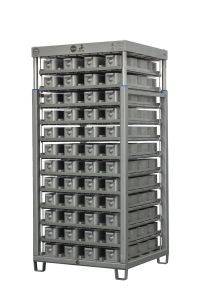

Multimould for turkey-shaped pieces. Normally used for making turkey ham.

- Type of base: Casters 2+2

- Capacity: 32 moulds

(4 × 8 levels) - Products per mould: 3

Multimould with a conical adjustment system between the lid and the mould to prevent ridges on the pieces. Oval-shaped pieces.

- Type of base: Fixed feet

- Capacity: 36 moulds

(4 × 9 levels) - Products per mould: 4

OUR SYSTEM’S ADVANTAGES

Our multimuold racks have been designed to facilitate the forming of meat pieces into molds. There are many advantages of our multimould system when compared to other alternatives on the market:

Over 2000 multimoulds working at full capacity in the most demanding conditions, in leading plants all over the world vouch for our system.

CHOICE OF MOULDS

Our moulds are made to measure in accordance with each client’s needs. We adapt the shape, number of dividers and size of the moulds to optimise each production system.

OPENING MOTOR TROLLEY

The easiest wat to open and press moultimould racks