DEMOULDING HAS NEVER BEEN SO EASY

Our exclusive demoulding systems are designed to facilitate and automate the moulding and demoulding of meat products cooked in the mould.

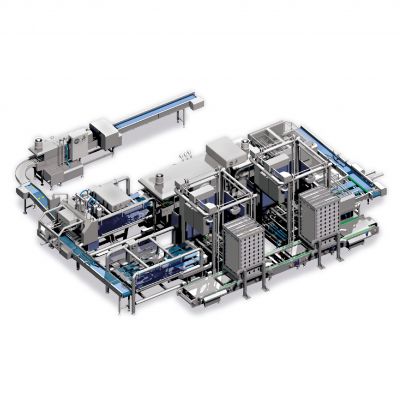

The different options we offer range from semi-automatic demoulding units designed to make the task more ergonomic, to fully automated lines intended for large-scale production.

In recent years we have implemented automatic guided vehicle (AGV) technology to manage and store the different multimould rack formats. This totally flexible technology perfectly complements our philosophy of automatic multi-format lines.

The main advantages are:

- Lines with expandable modular design. The design of the system makes it possible to complement the demoulding line, automating tasks such as unloading and extracting moulds, mould cleaning, loading moulds and even smart management of the different mould formats used on a line.

- Major workforce saving by avoiding difficult demoulding tasks traditionally done manually by operatives.

- Multiformat line system. Our system makes it possible to work with pieces of different shapes and sizes with a simple format change.

- High production capacity of up to 7 multiple moulds per minute.

- Exclusive air injection demoulding system. Our system ensures total demoulding reliability while at the same time avoiding internal product breakage caused by extraction suckers. Patented system. Pat. no. P 200 700 558

ERGONOMIC DEMOULDER

The perfect demoulder for making the switch to our renowned compressed air demoulding system. Designed for volumes of up to 15 tonnes/day, it is the perfect compromise between productivity and ergonomics without damaging the moulds or the product during demoulding operations. It can be complemented by a practical and efficient automatic mould lifting system.

SEMI-AUTOMATIC DEMOULDING LINE

Unit designed to produce up to 50 tonnes/day, it is the first step towards full automation. The tasks performed by the basic unit are fully automated unloading of the multimould and compressed air demoulding. As it operates with a PLC, it is fully expandable with accessories such as: mould washing tunnel, rack loaders, automatic moulding of bars for slicing, etc.